- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

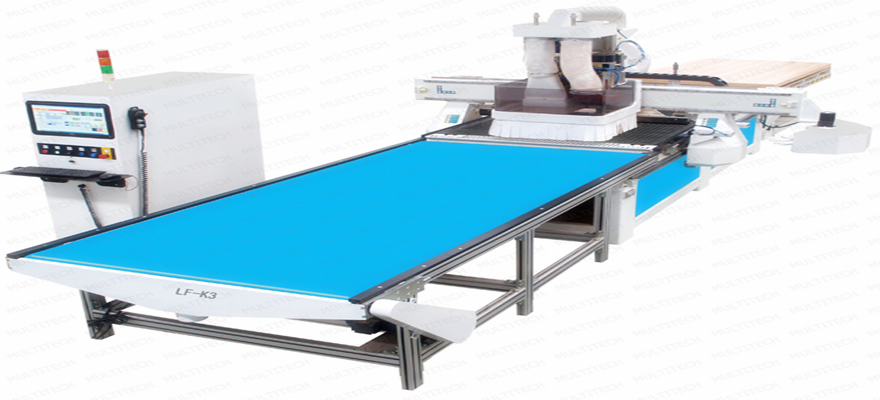

- Size: 1870*1340*1220mm

- Place of Origin: Jinan

- Brand Name: philicam multitech

- Model Number: ITM1325L

- Weight: 1500.000 kg

professional 1325 office furniture cnc router

Performance characteristics :

1. fission key board control,ensure users operate easily.

2. Advanced Taiwan syntec control system,Intelligent processing cross

border protection function,can prevent mechanical impact caused by the improper design documents. and control the processing speed,improve the processing efficiency .

3. Dust collection suck the wood chips,keep the working table clean. Vacuum table can absorb the material, save the plate loading and unloading time.

4. Advanced file preprocessing function,help users to correct errors in a timely. And be Be compatible with several CAD/CAM/alphacam designing software

5. Recover caving point after break of disconnecting power.Automatic error correction function guarantee the engraving precision for long time processing.

6. Lathe bed welded with seamless steel tube,not easy to be deformed.

Application:

1. Panel furniture, Cabinet production, Office furniture, Custom-made furniture etc.

2. Automated loading and unloading of the sheet materials bringing high-volume cabinetry to the woodworking industry and high-volume sheet fabrication to the plastics industry.

3.This Multitech 1325 office furniture cnc router is designed with with the high production shop in mnd, based and compatible with cabinet vision and alphacam design programs.

The customer is able to streamline the material handling, CNC routing, and offloading operations, seamlessly and efficiently.

professional 1325 office furniture cnc router

Performance characteristics :

1. fission key board control,ensure users operate easily.

2. Advanced Taiwan syntec control system,Intelligent processing cross

border protection function,can prevent mechanical impact caused by the improper design documents. and control the processing speed,improve the processing efficiency .

3. Dust collection suck the wood chips,keep the working table clean. Vacuum table can absorb the material, save the plate loading and unloading time.

4. Advanced file preprocessing function,help users to correct errors in a timely. And be Be compatible with several CAD/CAM/alphacam designing software

5. Recover caving point after break of disconnecting power.Automatic error correction function guarantee the engraving precision for long time processing.

6. Lathe bed welded with seamless steel tube,not easy to be deformed.

Application:

1. Panel furniture, Cabinet production, Office furniture, Custom-made furniture etc.

2. Automated loading and unloading of the sheet materials bringing high-volume cabinetry to the woodworking industry and high-volume sheet fabrication to the plastics industry.

3.This Multitech 1325 office furniture cnc router is designed with with the high production shop in mnd, based and compatible with cabinet vision and alphacam design programs.

The customer is able to streamline the material handling, CNC routing, and offloading operations, seamlessly and efficiently.

Here's how the professional 1325 office furniture cnc router works:

This CNC Processing Center1325 will automatically load a 4x8 sheet from a pallet by way of a scissor lift located at the rear of the CNC machine and a movable gantry system equipped with suction cups.

The material sheet is safely and accurately guided onto the CNC platform by the gantry using retractable guide rails and stops on the table.

Once the sheet is placed, the operator turns on the vacuum hold down and starts the cut cycle for the CNC to execute.

After the sheet is fully processed, it is then pushed off to a conveyor table at the front end while another sheet is simultaneously loaded from the rear of the machine again.

During this whole process the residual dust, that is not picked up from the dust collector, is swept off the table and conveyor into various chutes keeping the work cell clear of dust and debris.

Upon completion, the individual parts are labeled by the operator through an integrated bar code system.

This facilitates clear identification of the finished parts for quick and easy assembly later on.

Our Services

During sale:

We would deal with all the production and shipping affairs,after everything is ready,we would tell you everything goes well here;

After sale:

We would provide English Version working manual.

If you have any questions during using and maintaining,our engineers who could speak very good english would answer you online or by calls.

Machine warranty is two years.So if your machine has any unintentional damages,we would provide parts for free.

If your machine has big problems if by any chance,our engineers would arrive there to debug and fix.

Could be remote control if needed.

24 hours life time after sale service.

Guaranty

1.Twoyearsquality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge when if there is any problem during the warranty period.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.We will provide the consumable parts at an agency price when you need replacement.

5.24 hours on line service each day, free technical support.

6.Machine has been adjusted before delivery.

Why ITECH CNC?

1.We provide you a solution and not just a machine

2.Well configured machine using hardware that makes the machine efficient, accurate, and reliable.

3.Feel Confident when buy from a CN company that has expert staffs with over 10 years of CNC building experience.

4.Get the support that you deserve from our confident well trained staff members.

5.ITECH prides itself in having the patience and the ability to provide knowledge and service.

Packaging & Shipping

The advantages of Plywood Case Package:

1.plywood case, its compressive strength and bearing quality is better, is the market ofchoice for the goods of high-weight packaging;

Secondly , the board area is big, the soil structure is good,and operational process is simple,So its is better in leak proof ness and waterproof;

Thirdly , when importing the plywood case is with fumigation-free ,

theprocedure is simple.

2.The normal package is standard plywood packages.(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

If you have a need on our products, just please feel free to contact me without hesitation.

- Size: 1870*1340*1220mm

- Place of Origin: Jinan

- Brand Name: philicam multitech

- Model Number: ITM1325L

- Weight: 1500.000 kg

Technical Parameters

Model | ITM1325 L | |

Working travel | X axis | 1300mm |

Y axis | 2500mm | |

C axis | 200mm | |

Table structure | Vacuum suction | |

Rail | HIWIN or PMI square rail | |

Transmission type | X,Y Rack,Z Ball Screw | |

Repositioning accuracy | ±0.05 | |

Working accuracy | ±0.05 | |

Max air move speed | 25000mm/min | |

Max working speed | 12000mm/min | |

Spindle parameters | Type of cooling | Hitech air cooling spindle |

power | 9.0kw | |

speed | 0-24000r/min | |

Drilling head | Hitech 5 4 | |

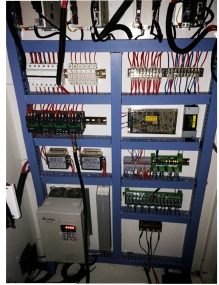

inverter | Delta inverter | |

Drive system | 750w YASKAWA servo motor | |

Command code | G code | |

Control system | Syntec | |

Transmission | X,Y-axis gear transmission, z-axis ball screw | |

Oiling system | Automatic | |

Working voltage | 3 phase AC380V/50HZ | |